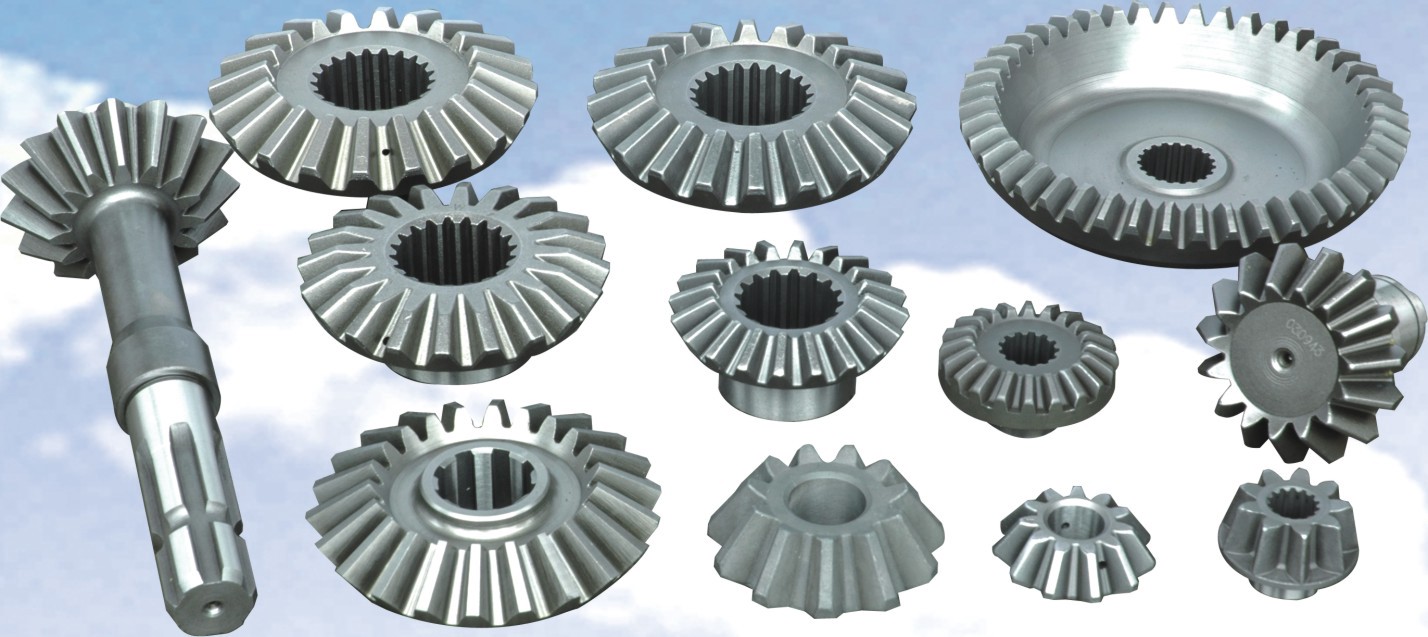

O mea fa'apipi'i e fa'aaogaina e felauai ai le fegasoloa'iga ma le malosi i le va o la'au felavasa'i e lua. I masini lautele, o le tulimanu o le fesoʻotaʻiga i le va o laʻau e lua o mea faʻapipiʻi e tutusa ma le 90 ° (ae atonu e le tutusa ma le 90 °). E taitutusa ma mea fa'akomupiuta, o mea fa'apipi'i e iai fa'aigoa fa'asinomaga, fa'aopoopo fa'aopoopo, a'a nifo ma fa'amau fa'avae. O le cone e iai lona pito tele ma se pito itiiti, ma o le li'o e fetaui ma le pito tele e ta'ua o le li'o fa'asino (o lona radius o le r), o le li'o faaopoopo, o le li'o a'a ma le li'o faavae. O le fa'agaioiina o se pea o mea fa'aoga fa'apipi'i e tutusa ma se pea o fa'ama'i fa'amau mo le ta'avale mama.

Le fa'avaeina o fa'ailoga nifo:

O le fa'avaeina o le fa'ailoga o nifo o mea fa'apipi'i e tutusa ma mea fa'aoga fa'ato'aga, se'i vagana ai le fa'aoga fa'avae e fa'aoga nai lo le fa'a'au'au fa'avae. O le mea fa'atupu S o lo'o fa'atatau i le generatrix o le fa'amau fa'avae. A o'o ina ta'avale lelei le mea fa'atupu S i luga ole cone fa'avae, so'o se laina sa'o OK ile luga ole mea fa'atupu fa'afeso'ota'i le generatrix ON o le cone fa'avae ole a fa'atupuina se fa'aoga fa'aoga i luga ole vateatea. O le mea fa'apipi'i lea o le fa'ailoga nifo fa'afefeteina o le mea fa'aoga sa'o. O le ala o itu taitasi i luga o le laina OK o se involute (o le involute i le tumutumu O o se mata). O vaega ta'itasi i luga o le NK involute e tutusa le mamao mai le cone O, o lea e tatau ona i ai le involute i luga o se mea lapotopoto e totonugalemu i luga o le cone O ma o le radius e OK, o lona uiga, NK o se spherical involute.

mataupu silisili:

O nifo ma avanoa o nifo o mea faʻapipiʻi ua faʻapipiʻi uma, o lona uiga, e lautele i le pito tele ma le vaapiapi i le pito itiiti. E ui lava o le ulu o le faasino igoa ua siitia i luga o le aʻa aʻa i le taimi o le gaioiga, o le pito tele o le pito i fafo o le pito i fafo o mea faʻapipiʻi e sili atu le maualuga nai lo le pito laʻititi, ma o le pito tele e tipi loloto atu nai lo le pito laʻititi i le taimi o le viliina, ma o le lautele o le tootoo nifo e sili atu foi nai lo le pito tele. O le pito laʻititi e laʻititi laʻititi, ae o lenei eseesega e le mafai ona ausia manaʻoga. E mana'omia le viliina atili i itu uma e lua o le pito tele. Pe a vili bevelled gears i luga o se masini vili, ina ua uma ona viliina le nifo ogatotonu slot mo le taimi muamua, ua maua le talaaga nifo o le pito tele, ae o le slot lautele fua e le ausia manaoga. O le mea lea, e mana'omia e ta'itasi nifo ta'i faatolu ona viliina e ausia. O le mataupu faavae o le vili fa'a-offset o le: i le tasi itu, o le mea faigaluega e fa'afefe; i le isi itu, ua siitia le worktable e realign le toga nifo pito itiiti ma le tipi vili. Faʻaaogaina o le eseesega offset i le va o le pito tele ma le pito laʻititi e faʻatatau i le itu fafaga (transverse) pe a faʻafefe le mea faigaluega, o le alauni vili e faasolosolo malie lava ona faʻateleina mai le pito laʻititi i le pito tele, ma o le pito tele e sili atu ona milled.

I le taimi nei, o loʻo i ai le tele o auala faʻafefeteina pe a viliina mea faʻapipiʻi, ae ona o le le tutusa o le fua faatatau o le pitch i le lautele o nifo (ie R / b), ma le eseesega i tapulaʻa e pei o le pitch angle ma le numera o. nifo, so'o se metotia e le mafai ona fa'aoga i cones uma. O le mea lea, e mafai ona filifilia e tusa ai ma tulaga faʻapitoa ma faʻasaʻo i le tipiina o faʻataʻitaʻiga. E masani ona faʻaaoga le tuʻufaʻatasiga o le taamilosaga ma le faʻaogaina mo le viliina.

bevelled gears production process:

1. First, use the hobbing principle to make the machined gear and the imaginary shovel gear repeatedly perform relative hobbing. The tool is a planer with two straight cutting edges, installed on the tool holder, and reciprocating with the tool holder Linear motion.

2. O lo'o fa'apipi'i le fa'amau meafaigaluega i luga o le moega pepe e fai ai se mea fa'aoga suo. O le suo fa'ata'ita'i fa'ata'ita'i swings mai luga i lalo ma mai lalo i luga fa'ata'amilo i lona lava laina axis, ma fa'apipi'i le mea fa'agaioia i luga o le 'au autu o le atigipusa atigipusa, ma fa'agaoioi le atigipusa pito i lalo e fai ai le pito bevel. o le mea e fa'agaioia ma le suo fa'afoliga fa'ameamea fa'amea fa'ata'amilosaga Fa'atasi, ma fa'ata'ita'i le a'a nifo nifo ma le pito e pasia e le pito o mea faigaluega.

3. During gear cutting, the cradle and the gear to be machined respectively make coordinated movements around the axis, that is, as if two bevelled gears mesh, the gear to be machined will be machined under this installation.

4. The axis line and the rotary axis line of the cradle intersect at a point, which is the center of the machine tool. Such mutual movement enables the planer to plan out the correct involute tooth profile.

According to the number and modulus of the workpiece, it is determined to plan the gear with the single tooth method or the double tooth method. For single-piece small-batch production, the single-tooth method is generally used to plan gears.

Spiral bevelled gears have high transmission efficiency, stable transmission ratio, large arc overlap coefficient, high carrying capacity, stable transmission, reliable work, compact structure, energy saving and material saving, space saving, wear resistance, long life and low noise.

The advantages of spiral bevelled gears (compared with straight bevelled gears):

1. Increase the contact ratio, that is, increase the overlap coefficient, reduce the impact, stabilize the transmission, and reduce the noise.

2. The load specific pressure is reduced, the wear is more uniform, the load capacity of the gear is increased correspondingly, and the service life is long.

3. A large transmission ratio can be implemented, and the number of small wheels can be as few as 5 teeth.

4. The tooth surface can be ground to reduce noise, improve the contact area and improve the tooth surface finish. The precision of gear grinding can reach level 5.

Spiral bevelled gears are widely used in printing equipment, automobile differentials, and sluices. They can also be used in locomotives, ships, power plants, steel plants, railway track inspections, etc. Compared with metal gears, plastic gears are economical, have a long wear-resistant life, and are highly functional.

Fa'ailoga o mea fa'apipi'i:

Long life, high load carrying capacity

Malosi kemikolo ma le pala

Fa'aitiitia le pisapisao ma le vibration

Mamafa mama ma tau maualalo

Faigofie ona fai, lubricity lelei

Fa'asa'oga o le mafiafia o nifo i le taimi o le viliina o le afi:

After offset milling on both sides of 2 to 3 teeth with the above method, the large and small ends of the teeth should be inspected. If the actual measured value does not match the value marked on the drawing or calculated, you need to correct the amount of rotation and offset. The principle of correction is:

1. If the size of the small end is accurate and there is margin for the big end, the amount of rotation (or deflection angle) and offset should be increased to increase the difference so that the small end is no longer milled.

2. If the size of the big end is accurate and the tooth thickness of the small end has a margin, the amount of rotation (or deflection angle) should be reduced to reduce the offset more. The small end is also milled away, and the big end is no longer milled.

3. If both the big end and the small end have margins, and the margins are equal, only need to reduce the offset so that both the big end and the small end are milled off.

4. If the size of the small end is accurate and the size of the big end is too small, the amount of rotation (or deflection angle) should be reduced, and the offset should be appropriately reduced so that the small end is no longer milled off, and the big end is cut less than the original some.

5. Afai o le tele o le pito tele e saʻo ma o le tele o le pito laʻititi e laʻititi tele, e tatau ona faʻateleina le aofaʻi o le taamilosaga (poʻo le faʻaogaina o le angle), ma e tatau ona faʻatuputeleina le faʻasalaga, ina ia faʻateleina le pito laʻititi. ili itiiti ifo nai lo le mea muamua. Afai e laʻititi tele le mafiafia o le nifo o le pito laʻititi pe a viliina le vaeluagalemu, e tatau ona e suitulaga i le tipi vili pe fai se tipi faʻapitoa mo le gaosiga.

O le mea e fa'atatau i se mea fa'ainisinia o lo'o i ai fa'a'au i luga o le au'a e fa'aauau pea ona fa'alava e fa'asalalauina le gaioiga ma le malosi. O le faʻaogaina o mea e faʻaogaina i le felauaiga na faʻaalia vave. I le faaiuga o le seneturi lona 19, o le mataupu faavae o le gaosiga o mea e tipi ai meafaigaluega ma meafaigaluega faapitoa masini ma meafaigaluega na faʻaaogaina lenei mataupu faavae e tipi ai mea na faʻaalia i le isi. Faatasi ai ma le atinaʻeina o le gaosiga, o le faʻalelei o le faʻaogaina o mea faʻaoga sa gauai atu i ai.

Fa'avasegaga o le fausaga:

Generally, there are gear teeth, tooth grooves, end faces, normal faces, addendum circles, tooth root circles, base circles, and index circles.

Nifo tu'u

Referred to as a tooth, it is each convex part of the gear used for meshing. These convex parts are generally arranged in a radial pattern. The teeth on the mating gears are in contact with each other, so that the gears can continuously mesh and run.

Cogging

It is the space between two adjacent gear teeth on the gear; the end face is on the cylindrical gear or cylindrical worm, and the plane perpendicular to the axis of the gear or worm.

Fa'ai'u foliga

It is the plane at both ends of the gear.

Dharma

Refers to the plane perpendicular to the tooth line of the gear.

Li'o faaopoopo

Refers to the circle where the tip of the tooth is located.

Li'o a'a nifo

Refers to the circle where the bottom of the groove is located.

Li'o faavae

The generating line forming the involute is a purely rolling circle.

Li'o fa'asino

It is the reference circle for calculating the geometric dimensions of the gear in the end face.

fa'avasegaga:

E mafai ona fa'avasegaga tu'uaga e tusa ai ma foliga o nifo, foliga o mea, foliga laina nifo, luga o lo'o i ai nifo, ma auala o gaosiga.

O le fa'ailoga nifo o le mea fa'aoga e aofia ai le pupuni o le fa'ailoga nifo, le fa'amauga, maualuga o nifo ma le suiga. E sili atu ona faigofie le gaosiga o mea fa'aonaponei, o mea fa'aonaponei, o mea fa'aonaponei e fa'atatau i le to'atele, a'o le fa'aogaina o mea e fa'aoga ai le cycloid ma arc.

E tusa ai ma le maualuga o le mamafa, o mea taʻavale e laʻititi laʻititi laʻititi o loʻo i ai se laʻititi laʻititi le gafatia o le avega; o mea e faʻaogaina ai le tele o le mamafa o le mamafa o loʻo i ai le maualuga o le avega, ae o le avega i luga o le faʻatupuina o loʻo faʻateleina i lalo o le faʻasalalauga tutusa, o lea e naʻo le faʻaaogaina i tulaga faʻapitoa. O le maualuga o nifo o le mea e faʻaogaina ai ua faʻatulagaina, ma o le maualuga o nifo masani e masani ona faʻaaogaina. E tele faʻamanuiaga o mea faʻaogaina, lea na faʻaaogaina lautele i masini masini eseese.

E le gata i lea, e mafai foʻi ona vaevaeina mea faʻapipiʻi i mea faʻaoga faʻaoga, mea faʻapipiʻi, mea e le faʻataʻamilomilo, fata, ma anufe e tusa ma o latou foliga; e tusa ai ma foliga o le laina nifo, e mafai ona vaevaeina i latou spur gears, helical gears, herringbone gears, ma curved gears; e tusa ai ma nifo faʻaoga O le pito i luga e vaevaeina i fafo ma mea i totonu; e tusa ai ma le auala o le gaosiga, e mafai ona vaevaeina i ni mea lafo, tipi tipi, taʻavale, ma sintered gears.

O le gaosiga o meafaitino ma le faʻaogaina o le vevela o le mea e faʻaogaina ai le faʻaogaina o le mea e faʻaogaina ai le malosi o le uta ma le mamafa ma le mamafa o mea faʻaoga. A'o le'i o'o i le vaitau o le 1950, sa masani ona fa'aogaina le uamea kaponi mo mea fa'aoga, ua fa'aaogaina le sila uamea i le vaitau o le 1960, ma le uamea fa'ama'a'a sa fa'aaogaina i le 1970s. E tusa ai ma le maaa, e mafai ona vaevaeina luga o nifo i ni ituaiga se lua: luga o nifo vaivai ma luga o nifo malo.

O mea e iai nifo vaivai e maualalo le gafatia e ave ai uta, ae sili atu ona faigofie ona gaosia ma lelei le faʻatinoina. E masani ona faʻaaogaina i masini lautele e aunoa ma se faʻatapulaʻa faʻatapulaʻaina i luga ole lapopoa ma le mamafa, ma le gaosiga laiti. Talu ai ona o le uili laʻititi e sili atu le mamafa i totonu o mea e fetaui, ina ia mafai ai ona tutusa le olaga galue o le tele ma le laʻititi laʻititi, o le maaa o le nifo o le uili laʻititi e masani ona maualuga atu nai lo le uili tele.

O mea faʻamaʻa faʻamaʻa e maualuga lona gafatia e ave ai uta. A uma ona tipiina ia mea, ona tineia lea, tineia i luga po o le carburized ma tineia e faateleina ai le maaa. Ae i le vevela vevela, o le a mautinoa lava le faʻaleagaina o le mea, o lea pe a maeʻa togafitiga vevela, olo, olo poʻo le tipiina lelei e tatau ona faʻatinoina e faʻaumatia ai le mea sese e mafua mai i le faʻaleagaina ma faʻaleleia le saʻo o le mea.

meafaitino

O uʻamea masani faʻaaogaina mo le faʻaogaina o mea e faʻafefeteina ma faʻafefete, uʻamea tineia, uamea faʻamaʻi ma tineia ma uamea nitrided. O le malosi o le u'amea lafo e la'ititi la'ititi nai lo le u'amea u'amea, ma e masani ona fa'aaogaina mo mea tetele; u'amea lafo efuefu e leaga mea fa'ainisinia ma e mafai ona fa'aoga i le fa'aogaina o mea fa'aoga mama; u'amea ductile e mafai ona sui vaega u'amea e fai ai mea; e masani ona fa'aoga mea palasitika I nofoaga e mana'omia ai le uta mama ma le pisapisao, e masani lava ona fa'aogaina e mea fa'apipi'i u'amea ma lelei le fa'amama.

In the future, gears are developing in the direction of heavy load, high speed, high precision and high efficiency, and strive to be small in size, light in weight, long life and economical and reliable.

O le atinaʻeina o faʻataʻitaʻiga o mea faʻaoga ma tekinolosi gaosiga o le a suʻesuʻeina atili ai le faʻaogaina o le faʻaleagaina o nifo, o le faʻavae lea mo le faʻavaeina o se metotia faʻatusatusaina o le malosi faʻatuatuaina, ma le faʻavae faʻavae mo le faʻaleleia o le gafatia o le uta ma faʻalauteleina le ola; o le atinaʻe o loʻo faʻatusalia e le arc tooth profile Le fou nifo nifo; su'esu'e mea fa'aoga fou ma fa'atekonolosi fou mo le gaosiga o masini; su'esu'e le fa'asolosolo fa'asolosolo o mea fa'apipi'i, gaosiga ma fa'apipi'i mea sese, ma le fa'asoaina o fanua vevela, ma fa'aleleia le fa'aogaina o nifo e fa'aleleia atili ai le fa'alelei o le fa'aogaina o masini. Pe a faʻateleina le vaega faʻafesoʻotaʻi o nifo faʻaoga, ina ia faʻaleleia atili le gafatia o le mea e faʻaogaina.

Friction, lubrication theory and lubrication technology are the basic work in gear research. Research on elastohydrodynamic lubrication theory, popularize the use of synthetic lubricating oil and appropriately add extreme pressure additives to the oil, which can not only improve the bearing capacity of the tooth surface, but also It can also improve transmission efficiency.

The difference with hypoid bevelled gears:

Spiral bevelled gears and hypoid bevelled gears are the main transmission modes used in automobile final reducers. What is the difference between them?

O to'i autu ma fa'aulu e felavasa'i i se mea, ma o le tulimanu o le va'aiga e mafai ona fa'asa'oloto, ae i le tele o axles ta'avale ta'avale, o le pa'u fa'aitiitiga autu e fa'aogaina le fa'atulagaina o le 90 °. Ona o le fa'apipi'i o foliga pito o nifo fa'ato'aga, a itiiti ifo ma le lua pe sili atu pea o nifo fa'ato'aga e masoa i le taimi e tasi. O le mea lea, e mafai e mea fa'apipi'i fa'apipi'i fa'ata'amilo ona amo se uta tele. E le gata i lea, o nifo e le faʻaogaina i le taimi e tasi i luga o le umi atoa o le nifo, ae faasolosolo malie le tasi pito e faʻaauau pea ona liliu i le isi pito, ina ia galue lelei, ma e oʻo lava i le saoasaoa maualuga, o le pisa ma le vibration e matua tele lava. laiti.

O to'i o mea e fa'aosoina e le felavasa'i ae felavasa'i i le vateatea, ma o le va'aiga va'ava'ai e fa'aaogaina ai fo'i le 90° angle eseese va'alele auala tu'usa'o. O le mea e ave ai le mea e fa'atatau i luga po'o lalo e fa'atatau i le mea e fa'aosoina (fa'aigoaina o le pito i luga po'o le pito i lalo e tusa ai). A tele le fa'a'ese'esega i se tulaga fa'apitoa, e mafai e le tasi 'au fa'ato'aga ona pasi atu i le isi 'au fa'aoga. I lenei auala, e mafai ona faʻatulagaina faʻamau faʻapipiʻi i itu uma e lua o mea taʻitasi, lea e aoga mo le faʻaleleia o le malosi o le lagolago ma faʻamautinoa le saʻo o le faʻaogaina o nifo, ma faʻateleina ai le ola ola. E fetaui lelei mo axles ta'avale auala.

E le pei o mea fa'apipi'i ta'amilomilo, lea e tutusa ai le tulimanu o le mea e fa'aogaina ai le mea fa'apipi'i, ona e felavasa'i to'i o le pa'u, o le axis offset o le pa'u pa'u hypoid e sili atu ai le tulimanu o le mea fa'ata'avale. mea faigaluega. O le mea lea, e ui ina tutusa le fa'aogaina masani o le pa'u fa'apipi'i o le hypoid, e le tutusa le fa'ai'uga o foliga (o le fa'ai'uga o foliga o le mea e fa'ata'avale e sili atu nai lo le mea fa'avili). O le mea lea e maua ai e le mea e fa'ata'avale ai le mea e fa'aigoaina fa'amea fa'a-lua-fa'afa'ifa'ailoga e sili atu le lautele ma sili atu le malosi ma le fa'ama'a'a'a nai lo le mea e fa'ata'ita'iina ai mea e fa'apipi'i fa'ailo fa'ata'amilomilo tutusa. E le gata i lea, ona o le tele o le lautele ma le helix angle o le avetaʻavale o le hypoid bevelled gears transmission, o le faʻalavelave faʻafesoʻotaʻi i luga o le nifo e faʻaitiitia ma faʻateleina le ola tautua.

However, when the transmission is relatively small, the driving gear of the quasi-double-sided bevelled gears transmission is too large compared to the driving gear of the spiral bevelled gears. At this time, it is more reasonable to choose the spiral bevelled gears.

Spiral bevelled gears, namely spiral bevelled gears, are often used for movement and power transmission between two intersecting shafts. The teeth of the bevelled gears are distributed on the surface of a cone, and the tooth profile gradually decreases from the large end to the small end.

Faatomuaga:

The tooth profile of spiral bevelled gears is arc-shaped, and they are generally cone-shaped, like an umbrella shape, hence the name spiral bevelled gears.

Spiral bevelled gears is a transmission part that can be transmitted smoothly and with low noise according to a stable transmission ratio. It has different names in different regions. It is also called spiral bevelled gears, spiral bevelled gears, spiral bevelled gears, arc bevelled gears, Spiral bevelled gears, etc.

vaega:

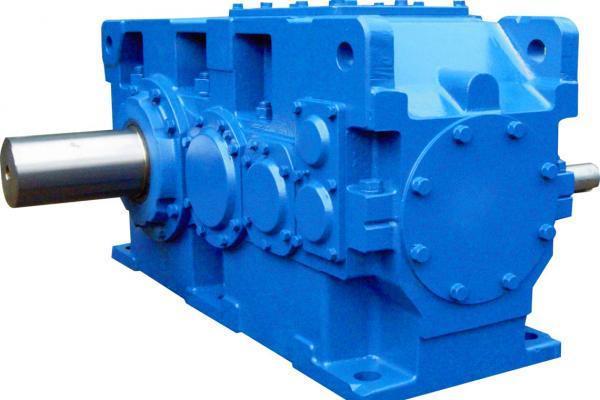

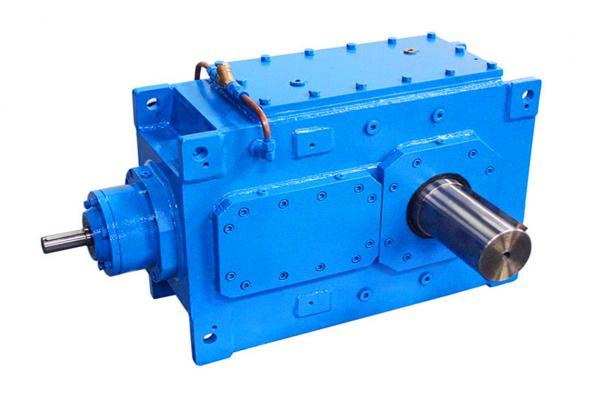

Spiral bevelled gears have high transmission efficiency, stable transmission ratio, large arc overlap coefficient, high carrying capacity, stable and smooth transmission, reliable work, compact structure, energy saving and material saving, space saving, wear resistance, long life and low noise.

Faatasi ai ma felauaiga faʻainisinia eseese, o le faʻaogaina lelei o mea faʻapipiʻi faʻapipiʻi e sili ona maualuga, lea e tele faʻamanuiaga tau tamaoaiga mo ituaiga eseese o faʻasalalauga, aemaise lava eletise maualuga. O le paipa fa'asalalau e mana'omia e fa'aliliuina ai le torque lava e tasi o le fa'aitiitiga fa'asao avanoa. O le avanoa e manaʻomia mo le faʻasalalau filifili e laʻititi; o le fua faatatau o felauaiga o mea ta'amilosaga ta'amilosaga e fa'amautu tumau, ma o fua fa'atatau o felauaiga mautu e masani lava o le mana'oga autu mo le fa'atinoina o felauaiga i le fa'asalalauina o masini masini eseese; e fa'amoemoeina mea e fa'apipi'i fa'ata'amilomilo ma e umi lona ola.

talosaga:

O mea faʻapipiʻi faʻapipiʻi e faʻaaogaina lautele i masini suauʻu i totonu o le atunuʻu ma fafo, masini masini eseese, masini masini masini, masini faʻainisinia, masini uʻamea, masini taʻavale uʻamea, masini mining, masini eliina koale, masini ie, masini fau vaa, fale fau vaa, aerospace, forklift, Elevators, reducers, gaosiga o vaalele ma le tele o isi pisinisi. O mea faʻapipiʻi faʻapipiʻiina e faʻaaogaina i le tele o mea faʻainisinia, e faʻaalia ai a latou faʻatinoga sili ona lelei, ma e taʻutaʻua i le gaosiga o meafaigaluega aerospace, fale vaʻa, masini faʻainisinia, masini faʻainisinia, masini faʻameamea, uʻamea taʻavale vaega faʻapitoa laau, uʻamea taʻavale masini masini, uʻamea vili mill, Fale masini u'amea, fale masini eliina, fale masini eli koale, fale suau'u petrochemical machinery, fale masini ie, fale meafaigaluega masini, kamupani masini, kamupani lifi, fale gaosi vaalele, fale fa'aitiitiga, fale masini eli koale, fale masini alamanuia mama, u'amea ta'avale u'amea, uamea ta'avale meafaigaluega falegaosimea, metallurgical meafaigaluega falegaosimea ma isi tagata fa'atau.

Faʻamolemole lagona le saoloto e faʻafesoʻotaʻi mai ma o lenei o le matou fesoʻotaʻiga. Matou te tali atu ia te oe i se taimi vave e mafai ai!

Mobile:+ 86-18563806647

Whatsapp / Wechat: 8618563806647

E-mail:

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, Saina(264006)

T + 86 535 6330966

W + 86 185 63806647